Hey there! Ever wondered about the electricity consumption of electric thermal oil heaters? Well, buckle up because I’m here to shed some light on this topic. Whether you’re considering one for your industrial setup or just curious, I’ve got you covered.

Electric thermal oil heaters can indeed use a significant amount of electricity, especially in industrial settings where they are employed for heavy-duty heating tasks. However, their power consumption can vary based on several factors, including the heater’s design, size, insulation, and usage patterns.

Stick around, and I’ll walk you through everything you need to know about electric thermal oil heaters and their electricity usage.

How To Choose An Industrial Electric Thermal Oil Heater?

Choosing the right industrial electric thermal oil heater is crucial for optimizing both performance and energy efficiency. Here’s what to consider:

- Heater Size and Capacity: Ensure the heater’s capacity matches your heating requirements without being oversized, which can lead to unnecessary energy consumption.

- Insulation Quality: Opt for heaters with efficient insulation to minimize heat loss and reduce electricity usage.

- Heating Element Type: Different heating element types, such as resistance heaters or infrared heaters, can have varying energy efficiency levels. Consider which type suits your needs best.

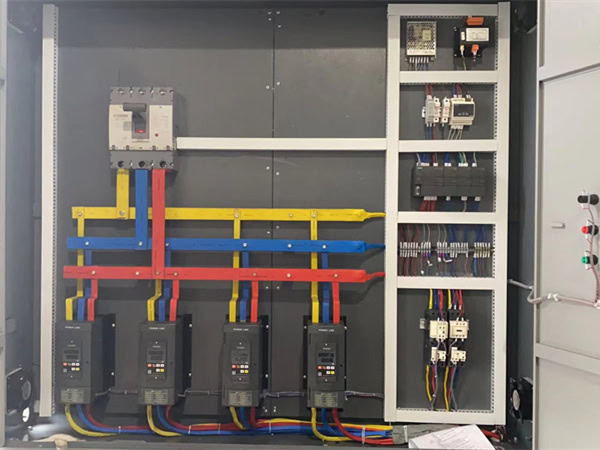

- Control Systems: Advanced control systems, like SCR power regulators, can help optimize energy usage by providing precise temperature control and reducing unnecessary heating cycles.

- Maintenance Requirements: Regular maintenance is essential to keep the heater running efficiently and avoid energy wastage due to malfunctioning components.

Let’s delve deeper into each of these factors to ensure you make an informed decision.

Factors Affecting Power Consumption

When it comes to the electricity usage of electric thermal oil heaters, several factors influence the overall power consumption:

- Heating Element Efficiency: The efficiency of the heating element directly impacts electricity usage. Higher efficiency elements consume less power for the same heating output.

- Insulation Quality: Proper insulation reduces heat loss, ensuring more efficient heating and lower electricity consumption.

- Control Systems: Modern control systems, such as SCR power regulators, offer precise temperature control, minimizing energy wastage.

- Usage Patterns: How frequently and for how long the heater is used also affects electricity consumption. Optimal scheduling and usage patterns can help minimize energy usage.

Vs. AC Contactor, Solid State Relay, and SCR Power Regulator:

When comparing different control systems for electric thermal oil heaters, it’s essential to understand their impact on electricity usage:

- AC Contactor: Traditional Contactors provide basic on/off control, but may result in energy wastage due to less precise temperature regulation.

- Solid State Relay: SSRs offer improved reliability and control compared to contactors, but may still lack the precision of advanced systems like SCR power regulators.

- SCR Power Regulator: SCR regulators provide precise temperature control, minimizing energy wastage and optimizing electricity usage.

Thermal Insulation Materials: Investing in high-quality insulation materials for your electric thermal oil heater can significantly reduce electricity consumption by minimizing heat loss.

The Distance Between Heating Equipment and Thermal Oil Heater: Reducing the distance between the heater and the equipment to be heated can minimize heat loss during transfer, resulting in lower electricity usage.

Heating Duration and Usage Patterns: Optimizing heating schedules and usage patterns can help minimize electricity usage by ensuring the heater operates only when needed and for the appropriate duration.

The Verdict: In conclusion, the electricity consumption of electric thermal oil heaters can vary depending on various factors, including the heater’s design, insulation, control systems, and usage patterns. By considering these factors and choosing wisely, you can optimize energy efficiency and minimize electricity usage in your industrial processes.

Comparing Electric Thermal Oil Heaters To Other Fuel Fired Heaters

While electric thermal oil heaters have their advantages, it’s essential to compare them to other fuel-fired heaters to make an informed decision:

Vs. Oil Fired Thermal Oil Heaters: Oil-fired heaters may have lower electricity consumption, but come with additional considerations such as fuel storage, emissions, and maintenance requirements.

Vs. Gas Fired Thermal Oil Heaters: Gas-fired heaters offer fast heating and may have lower operating costs depending on gas prices but require access to a natural gas supply.

Vs. Coal Fired Thermal Oil Heaters: Coal-fired heaters are less common due to environmental concerns, but may offer lower operating costs in regions where coal is abundant.

Calculating Energy Costs: Understanding energy costs is crucial for budgeting and optimizing efficiency:

Understanding Kilowatt-Hours (kWh): Kilowatt-hours measure energy consumption over time and are used to calculate electricity costs.

Conclusion: By considering factors such as insulation, control systems, and usage patterns, you can optimize the energy efficiency of your electric thermal oil heater and minimize electricity usage. Regular maintenance and monitoring are essential to ensure optimal performance and reduce energy wastage over time.

Tips For Optimizing Energy Efficiency

Here are some additional tips for maximizing energy efficiency:

- Proper Position of Electric Oil Heater: Install your thermal oil heater near the heated equipment, allowing the length from 3m-10m for optimal efficiency.

- Choosing the SCR Power Regulator: Utilize advanced control systems like SCR power regulators to optimize energy consumption.

- Insulating the Pipeline: Insulate pipelines to minimize heat loss during transfer and reduce the need for prolonged heating.

- Maintaining Your Electric Thermal Oil Heater: Regular maintenance ensures optimal performance and energy efficiency over time.

FAQs About Electric Thermal Oil Heaters

- Do Electric Thermal Oil Heaters Use A Lot Of Electricity? Electric thermal oil heaters can consume a significant amount of electricity, especially in industrial settings. However, their energy usage varies based on factors like size, insulation, and control systems.

- How Much Electricity Does An Electric Thermal Oil Heater Use? The electricity usage of an electric thermal oil heater depends on factors such as heater size, insulation quality, and control systems. Generally, they can use varying amounts of electricity based on the specific application and usage patterns.

- Are Electric Thermal Oil Heaters Expensive To Operate? Electric thermal oil heaters may have higher initial costs but can be cost-effective in the long run due to their energy efficiency and minimal maintenance requirements. Operating costs depend on factors like electricity rates and usage patterns.

- Are Electric Thermal Oil Heaters Better Than Other Fuel Fired Thermal Oil Heaters? Electric thermal oil heaters offer advantages such as precise temperature control, cleanliness, and ease of operation. However, the choice between electric and fuel-fired heaters depends on factors like availability of fuel, operating costs, and specific application requirements.

- How Often To Change The Thermal Oil? The frequency of thermal oil changes depends on factors like the quality of the oil, operating temperatures, and maintenance practices. Generally, it’s recommended to monitor the oil’s condition regularly and change it as needed to maintain optimal performance.

- Is It Difficult To Replace The Components & The Parts? Replacing components and parts of an electric thermal oil heater typically requires technical expertise and proper training. While some tasks may be straightforward, complex repairs or replacements should be handled by qualified professionals to ensure safety and proper functioning.

- Are Electric Thermal Oil Heaters Safe to Use? When installed and maintained correctly, electric thermal oil heaters are safe to use. However, it’s essential to follow safety guidelines, perform regular inspections, and address any issues promptly to minimize the risk of accidents or malfunctions.

- Are Your Electric Thermal Oil Heaters Certified? Our electric thermal oil heaters are certified by regulatory agencies or industry standards organizations like CE and ISO to ensure compliance with safety and performance standards. It’s essential to choose heaters that meet relevant certifications and standards for your specific application.

In conclusion, electric thermal oil heaters can indeed consume a significant amount of electricity, but their energy usage can be optimized through careful selection, proper maintenance, and implementation of energy-saving strategies. By considering factors such as heater capacity, insulation quality, control systems, and usage patterns, you can maximize efficiency and minimize electricity consumption, ensuring cost-effectiveness and environmental sustainability in your industrial operations.